Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

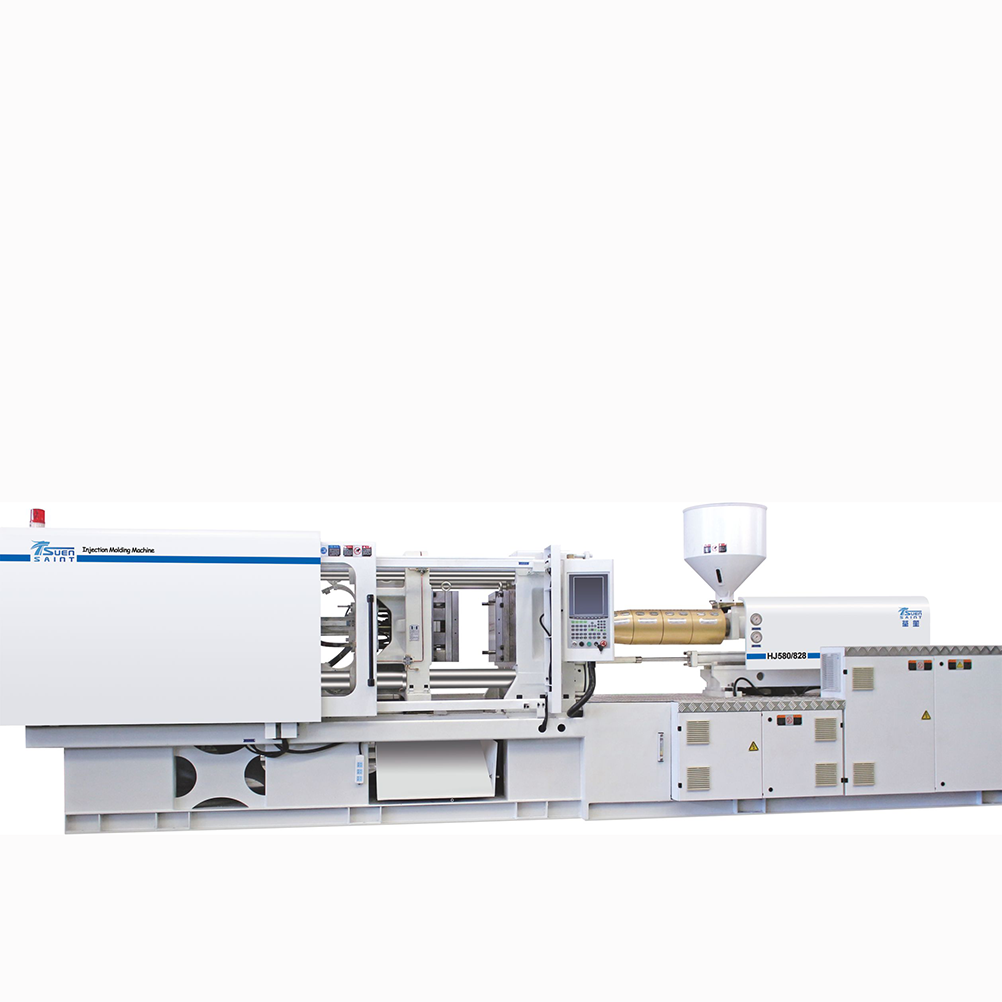

TSUENSAINT Nylon Kabelbinder Injection Molding Machine HJ/360-580T

The TSUENSAINT nylon strap cable tie injection molding machine (HJ/360-580T) boasts efficiency with a single-cylinder injection system and precision pneumatic self-locking nozzle. Specially designed for PA material, it ensures fast feeding, excellent plasticizing, and accurate temperature control. The increased oil circuit design meets fast molding requirements, while the Nano far-infrared heating device ensures rapid and energy-efficient plasticizing.

- Product Details

-

Download

Nylon Injection Molding Machine

Product Description

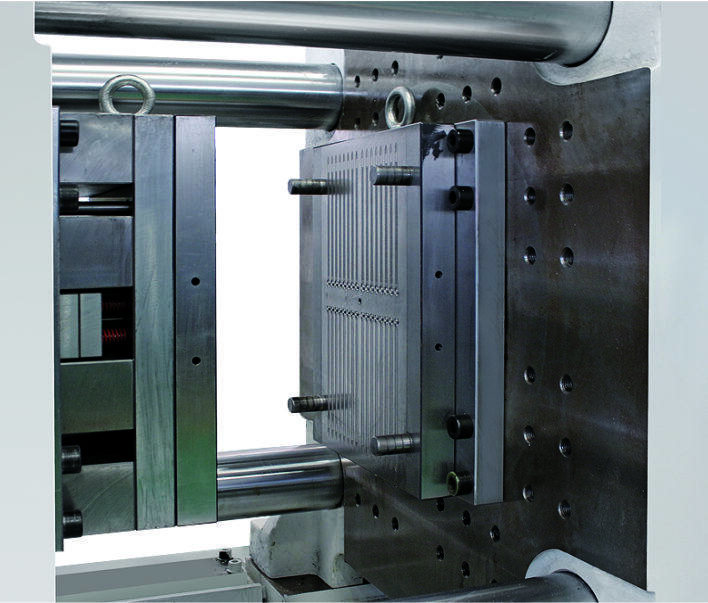

The TSUENSAINT HJ/360-580T nylon strap cable tie injection molding machine excels in precision molding. Its efficient single-cylinder injection system, precise pneumatic self-locking nozzle, and tailored screw and barrel assembly for PA material ensure swift and accurate production. With an advanced oil circuit design, it meets fast molding demands, and the Nano far-infrared heating device ensures quick heating, energy conservation, and superior plasticizing quality. This machine is a high-performance solution for Nylon strap cable tie production.

Product Features

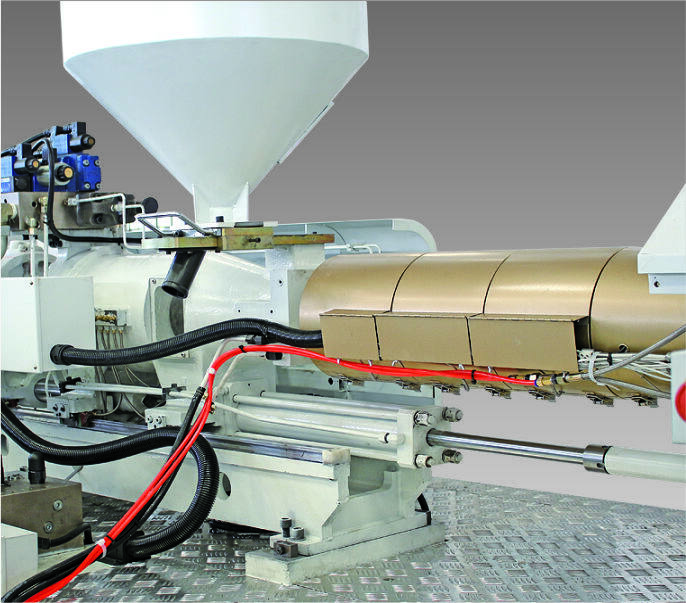

- Efficient Injection System: High-efficiency single-cylinder system for precise and swift molding of Nylon strap cable ties.

- Precision Pneumatic Nozzle: Equipped with a self-locking pneumatic nozzle for enhanced injection accuracy.

- Specially Designed Screw and Barrel: Crafted for PA material, enabling fast feeding, excellent plasticizing, and accurate temperature control.

- Venting and Draining Design: Incorporating a special design for venting and draining, contributing to improved plasticizing quality.

Product Advantages

- Precision Molding: Achieve precise molding of Nylon strap cable ties with the nylon injection molding machine's efficient single-cylinder injection system and precision pneumatic nozzle, ensuring accuracy in the production process.

- Material Adaptability: The specially designed screw and barrel for PA material enable the machine to handle fast feeding, excellent plasticizing, and precise temperature control. This enhances adaptability to various materials, increasing versatility.

- Enhanced Plasticizing Quality: The machine's venting and draining design contribute to improved plasticizing quality, guaranteeing high-quality and consistent output for Nylon strap cable ties.

- Operational Efficiency: Benefit from operational efficiency with the increased oil circuit design. This feature ensures high responsiveness, meeting the demands of fast molding requirements, and reducing downtime for optimized productivity.

Product Application

- Electrical and Electronics: Manufacturing cable ties for bundling and organizing wires in electrical and electronic devices.

- Automotive: Producing cable ties used in wire harnesses and cable management within vehicles.

- Construction: Creating cable ties for securing and organizing cables in construction projects.

- Packaging: Manufacturing cable ties for packaging applications, ensuring secure and organized packaging solutions.

HJ360ZD |

450/828 HJ450ZD |

||||||||

| Screw type | A | B | A | B | |||||

| Injection Unit | |||||||||

| Screw diameter | mm | 50 | 55 | 55 | 60 | ||||

| Screw L/D ratio | L/D | 26.4 | 24 | 27 | 24.8 | ||||

| Shot volume (theoretical) | CM3 | 441 | 534 | 593 | 706 | ||||

| Injection weight | g | 401 | 486 | 540 | 642 | ||||

| Injection rate | g/s | 320 | 400 | ||||||

| Injection pressure | Mpa | 574 | 695 | 865 | 1029 | ||||

| Injection speed | mm/s | 147 | 121 | 148 | 124 | ||||

| Screw speed | rpm | 350 | 350 | ||||||

| Clamping Unit | |||||||||

| Clamping force | KN | 3500 | 4200 | ||||||

| Open stroke | mm | 570 | 650 | ||||||

| Space between tie‑bars(W*H) | mm | 620×570 | 655×605 | ||||||

| Max. mould height | mm | 600 | 670 | ||||||

| Min. mould height | mm | 220 | 250 | ||||||

| Ejector stroke | mm | 100 | 100 | ||||||

| Ejector force | KN | 70 | 70 | ||||||

| Others | |||||||||

| Pump max. pressure | Mpa | 17.5 | 17.5 | ||||||

| Pump motor power (servo) | KW | 51 | 40+40 | ||||||

| Heating power | KW | 20 | 23 | ||||||

| Numbers of heating area | Segment | 3+1 | 3+1 | ||||||

| Machine dimension (L*W*H) | M | 6.54× 1.72×2.35 | 7.6 × 1.79×2.36 | ||||||

| Oiltank cubage | L | 600 | 800 | ||||||

| Machine weight | TON | 12 | 14.2 | ||||||

HJ520ZD |

580/828 HJ580ZD |

||||||||

| Screw type | A | B | A | B | |||||

| Injection Unit | |||||||||

| Screw diameter | mm | 55 | 60 | 60 | 65 | ||||

| Screw L/D ratio | L/D | 27 | 24.8 | 27 | 24.9 | ||||

| Shot volume (theoretical) | CM3 | 593 | 706 | 700 | 822 | ||||

| Injection weight | g | 540 | 642 | 637 | 748 | ||||

| Injection rate | g/s | 400 | 440 | ||||||

| Injection pressure | Mpa | 865 | 1029 | 1132 | 1329 | ||||

| Injection speed | mm/s | 148 | 124 | 135 | 115 | ||||

| Screw speed | rpm | 350 | 350 | ||||||

| Clamping Unit | |||||||||

| Clamping force | KN | 4700 | 5400 | ||||||

| Open stroke | mm | 705 | 730 | ||||||

| Space between tie‑bars(W*H) | mm | 685×660 | 730×675 | ||||||

| Max. mould height | mm | 670 | 750 | ||||||

| Min. mould height | mm | 250 | 300 | ||||||

| Ejector stroke | mm | 100 | 100 | ||||||

| Ejector force | KN | 70 | 70 | ||||||

| Others | |||||||||

| Pump max. pressure | Mpa | 17.5 | 17.5 | ||||||

| Pump motor power (servo) | KW | 40+40 | 51+40 | ||||||

| Heating power | KW | 23 | 27 | ||||||

| Numbers of heating area | Segment | 3+1 | 3+1 | ||||||

| Machine dimension (L*W*H) | M | 7.8 × 1.95×2.45 | 8.2 × 1.95×2.45 | ||||||

| Oiltank cubage | L | 850 | 1100 | ||||||

| Machine weight | TON | 16.8 | 22.5 | ||||||

Download

-

HJ.pdf

Download HJ.pdf